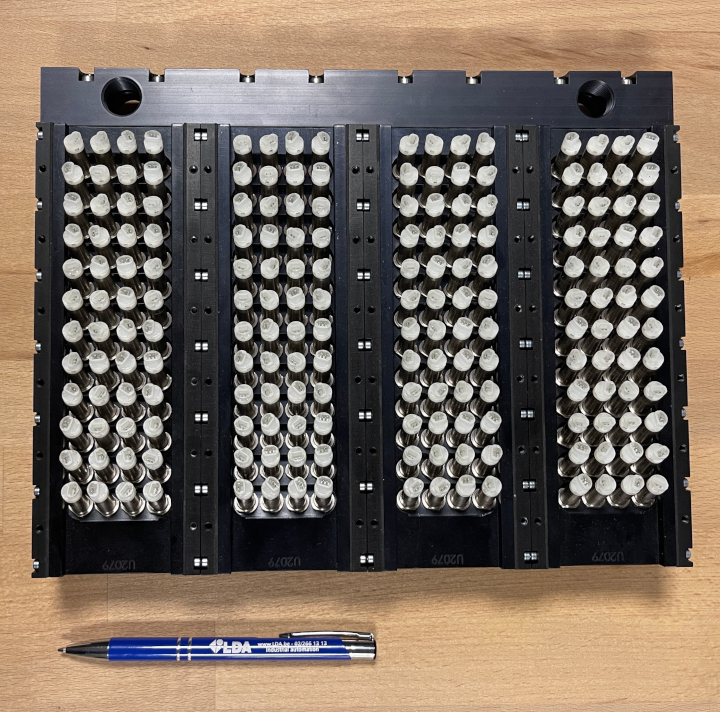

LDA sells gas springs for all industrial applications in which gas springs are used.

The extensive range, good quality and competitive prices have made us one of the largest gas springs suppliers in Belgium and Luxembourg.

LDA’s gas springs not only provide support for lids, hatches and other weights, but our real challenge lies in offering price competitive solutions for all our customers’ applications.

For many years, we have not just been a supplier of gas springs, but have built a relationship of trust with our customers.

Based on our many years of experience with gas springs and thanks to our technical “know-how,” our products serve various industries such as; automotive, furniture, machinery parks, transportation and automation.

Our large stock of gas springs and components usually allows us to help our customers within 24 hours.

Our technicians work closely with our customers to tailor a gas spring to their specific application. In addition, we have the ability to replace your old gas spring of any brand with an exact copy. For this we only need a technical drawing or sketch.

Our gas springs are continuously tested to ensure reliability, long life and overall product safety for your highest satisfaction.

Gas springs perform optimally when the correct internal gas pressure is applied.

LDA applies the right pressure in house, this guaranties that your Gas Spring has always the optimal pressure for your application.

The customer can also adapt the gas pressure on his Gas Spring. LDA measures than this pressure and will deliver all new Gas Springs according to those new specifications.

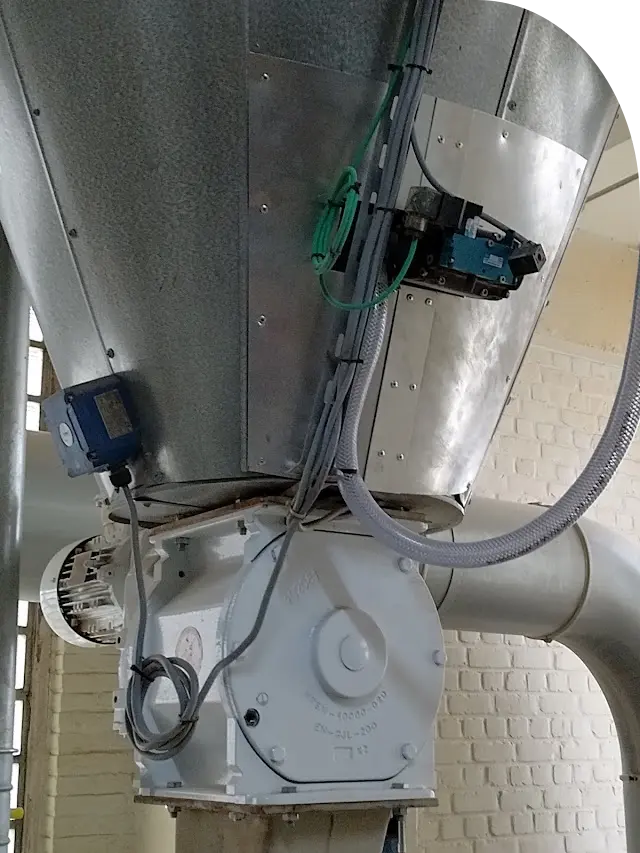

LDA has a service team equipped to perform on-site installations or maintenance at customer sites.

Our people hold the necessary safety certifications so that they can safely maintain or modify your important facilities.

To work quickly and efficiently, we have a fully equipped van at our disposal.

Our services include:

Most important, however, is the cooperation with your technicians. For us to succeed in your project, open communication between all parties is paramount. LDA will make sure that you are thoroughly briefed before we start work, only then can we succeed.

Our installation personnel hold various certifications such as:

Do not hesitate to contact us without any obligation, we are happy to listen to your problems and find an adequate solution to your question.

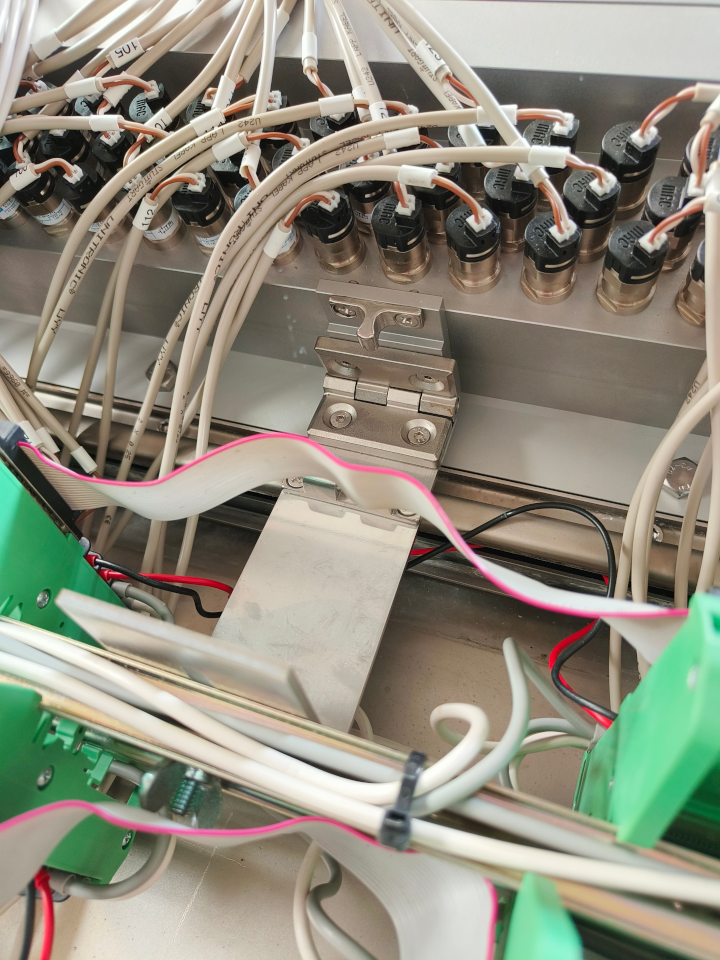

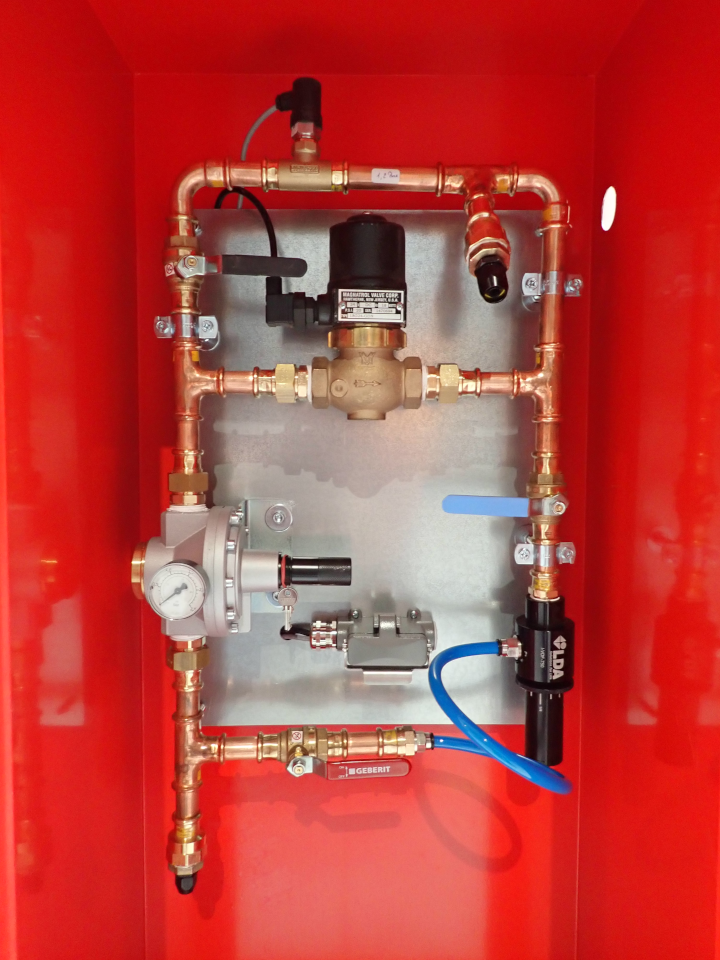

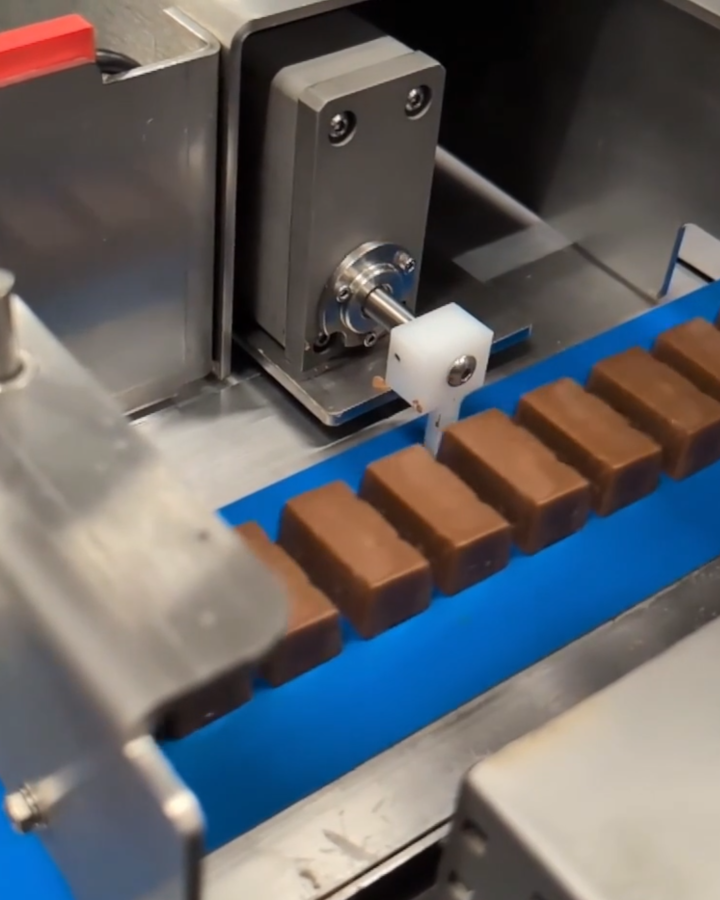

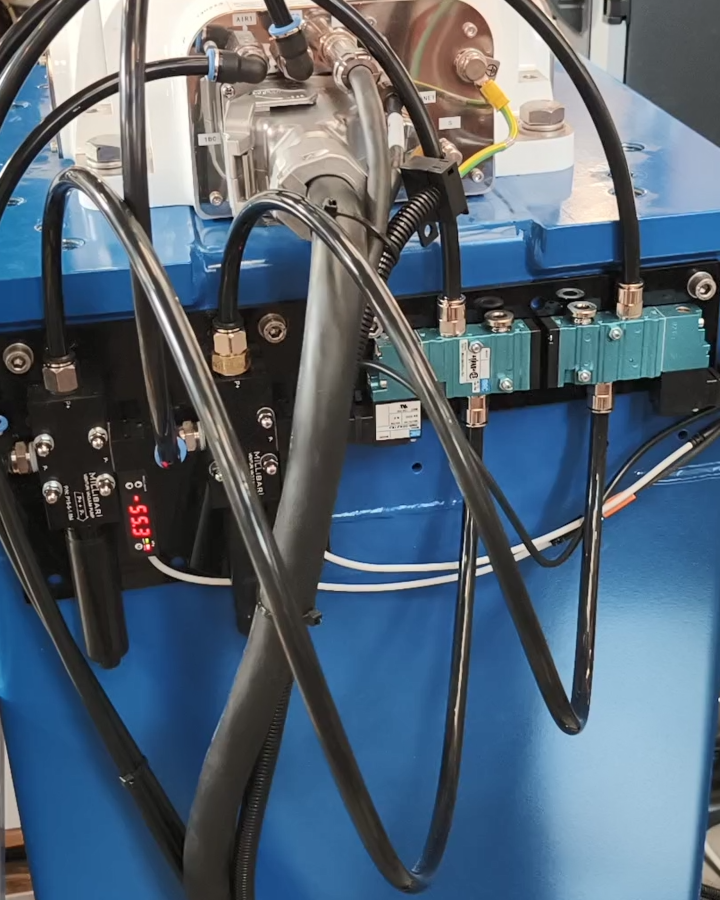

If you choose an automation solution with pneumatic or electrical parts, the implementation is often very complex, as you have to configure, document, procure and assemble numerous individual components from different suppliers. With our ready-to-install Components, you can save precious time for an affordable price. You only need to define the requirements and our project engineers will develop a solution in partnership with you. On the agreed date, you will receive a complete, tested package.

With us, you save valuable time at an affordable price thanks to our customer-specific solutions. Simply communicate your specifications to our project engineers, and together we will develop the ideal solution. You will receive a fully tested package that can be installed immediately, with minimal effort and maximum efficiency!

Custom Cables and Connectors

In addition to our expertise in pneumatic and electrical systems, we offer customized industrial cables and connectors. This ensures that your application perfectly matches your technical requirements.

Fully Assembled Kits:

Our assembly department provides fully assembled components and kits tailored to your choice of materials, packaging requirements and other specific needs. With just one part number, you will receive a completely tested and installation-ready component.

Tested and Reliable Systems.

We perform both electrical and pneumatic testing to ensure that your installation runs smoothly. This saves valuable time and minimizes unexpected complications.

Focus on Your Core Business

Let us handle assembly and testing so you can focus on your core business. Simplify your logistics process with easy ordering and just-in-time deliveries. Our engineers are ready to develop, install and, if necessary, assist in commissioning your application.

Global purchasing service:

Through longstanding global alliances and networks, LDA is able to efficiently source anything our clients require – anywhere – from highly trusted sources. Our partnerships allow us to achieve the ideal purchase: targeting value, product quality, and an optimal logistics solution to save time and money.

Our procurement clients expect and receive enhanced support for virtually all project requirements, reduced cost of labour, material delivery and a focused, low-risk acquisition process and systems.

Supply Chain Management:

LDA uses advanced methods and technologies within its distribution chain, allowing its customers to enjoy a fast and efficient delivery process.

Kanban deliveries, call-off contracts and the assembly and testing of various parts are among our expertise.

Quality control:

LDA provides efficient quality control upon delivery of its products. In specific cases, this is done in consultation with the customer in accordance with their business requirements.

During design, planning and execution, we continuously check the quality of the product delivered by us and our suppliers in accordance with our internal management system.

In doing so, we take steps as necessary to identify, report, correct and prevent deviation from requirements.

Support via subcontracting:

For decades, LDA has managed and operated some subcontracting activities. Our subcontractors support LDA and our customers because they are an integral part of LDA’s “Engineering, Procurement and Construction (EPC)” process. We commit ourselves and our subcontractors to always work in and safe and ethical manner.

Logistics management and optimization:

LDA biedt efficiënte, economische en stipte leveringen voor alle locaties in Europa.

Wij maken innovatief gebruik van onze kennis en gebruiken de nieuwste technologieën om de juiste oplossingen aan te bieden. Dit laat ons toe om proactief vertragingen te vermijden en een maximum aan klantentevredenheid te garanderen.

Material Management:

Over the past several decades, LDA has worked to help minimize our clients’ total material costs through innovative planning and logistics systems. We ensure the correct quality and quantity of materials, timely delivery of equipment to be installed, and subcontracted resources obtained at a reasonable cost, all available on-time and under budget.

LDA’s services samples are:

The MAC Distributor Network(MDN) is a global network of factory-certified experts in Compressed Air technology. Available around the clock and around the world, MAC distributors have deep knowledge of all MAC Valves and PHD products along with an overall knowledge of complementary lines.

Rather than providing a single product, the MDN offers entire solutions with the help of a responsive engineering and design team experienced in building new systems or making existing systems work better. Having a local MAC Valves and PHD distributor also means we can provide help in emergency situations, and quickly diagnose even the toughest of problems.

LDA is a proud member of the MDN global network of manufacturers and distributors working together to provide superior products, service and support to customers.

LDA and his partners within this global network are factory-trained and application-oriented. They carry all MAC Valves and PHD products and support the MAC Valves and PHD product customization process.

MDN offers the opportunity to blend the distributors’ unique expertise with that of the MAC Valves and PHD team. Together, we work to provide exceptional automation solutions and ongoing support to our customers around the world.

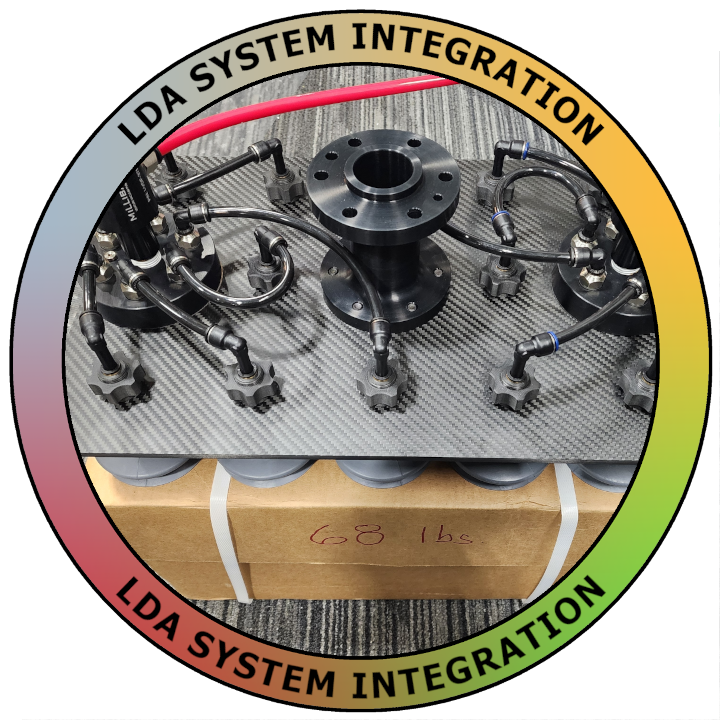

Did you know that LDA has a systems group dedicated solely to researching and implementing special projects on System Integration?

System integration refers to the process of merging various subsystems and software applications into one cohesive whole. This ensures that these systems work together effectively, enabling data exchange and process automation.

In the modern business world, organizations are increasingly dependent on technology.

With a growing number of systems and applications within companies, the need arises for additional support from specialists.

One of the key benefits of system integration is increased efficiency. In addition, your employees can focus on more strategic tasks, rather than spending time on one-time often difficult integration processes.

LDA has knowledge of these different technologies and can therefore assist you in the start-up or conversion phase of your new projects.

The different technologies we combine are:

In consultation with the client:

Do not hesitate to contact LDA and discuss your integration projects with one of our specialists without any obligation.

LDA

Hoge Buizen 53,

1980 EPPEGEM

VAT: BE0405.895.609

IBAN: KBC / BE51 7340 2410 9862

BIC: KBC / KREDBEBB

© LDA Belgium, all rights reserved.